Telescopic Slides: What They Are, What They Are for and How Many Types Are There?

Drawers are very common in everyone’s life, they come in different sizes and measurements, and are found in many pieces of furniture and other household, industrial or office equipment. There are different kinds of drawers, and to make them work efficiently, they are fitted with a telescopic guide that helps to develop the corresponding movement.

These devices slide the drawers with guided movements vertically and horizontally, to facilitate their closing or opening, and thus make their use more comfortable and safe. They are placed in small everyday objects, such as kitchen pantry drawers, and even in large industrial equipment in factories and processing plants.

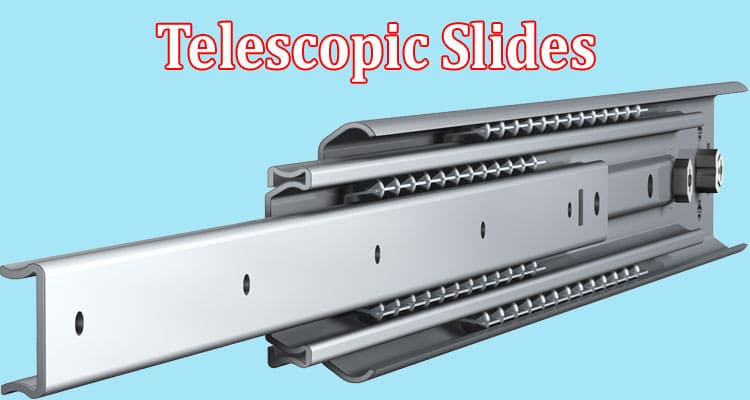

Their mechanism is composed of three articulated parts: the one attached to the cabinet, the one installed in the drawer, and the telescopic rail that extends and helps the drawer to move outwards. The continuous movement is due to the ball bearing, which facilitates the movement between the movable parts, in a comfortable and defined way.

In the case of industrial work, the heavy duty telescopic slide is used, which performs the same functions as the small drawer slides, but on a larger scale. These telescopic slides are manufactured in steel, stainless steel or aluminum, depending on their intended use. They are widely used in all types of industry to fulfill various functions and jobs that could not be performed without them.

Types of slides

There are several types of categories of telescopic slides for loading, which are differentiated by the characteristics they present and the functions they fulfill.

Among them, the following stand out:

- With partial extension: they have two compact elements and the travel is less than their closed length.

- With full extension: they are equipped with three elements and the device offers a stroke equal to its closed length.

- As well as with super extension: they have four elements, with a telescopic stroke that reaches up to 150% of its closed length.

- These devices are totally silent, withstand loads of up to 1,500 kilograms and can be extended to more than 3 meters. They adapt to all kinds of needs, with their open lock and closed lock options.

What are they used for?

Toughly tested, telescopic slides must be built with high-strength materials, not only because of the heavy weights they support, but also because of the inclement weather.

They are used for different purposes, among them:

- In the railway sector: by resisting vibrations and high loads, they are perfect for various tasks in that area.

- In the industrial sector: they are used in the casings of industrial equipment protection against any element that could damage them.

- Also in the electrical sector: telescopic slides fit very well in racks for electrical and electronic equipment.

- In the automotive sector: with special adaptations for specific functions needed inside any vehicle.

Characteristics of telescopic slides

This type of devices have different characteristics, which are used for different kinds of work in the industry:

Extension and length : depending on the model, folding lengths can range from 150 millimeters to more than 2 meters, and extension from a few millimeters to 3 meters.

Reinforcement of the slides: reinforced material balls are placed in the profiles to withstand heavy weights. Likewise, the slides are reinforced to withstand high torque forces without losing their smoothness.

Locking systems : some slides can be equipped with mechanical or manual locking systems, with different variations (open, closed and combined). They can also be fitted with ergonomic handles, which facilitate the process of opening and closing the system.

Synchronized guides : when all the elements work in a coordinated manner to optimize the displacement forces, the operation is much better and the life of all the components is extended. This is achieved with an integrated system that synchronizes everything perfectly.

Lubrication: depending on the use of the telescopic guide, a type of grease suitable for the operating conditions must be used. This has a great influence on its maintenance and better performance.

Advantages of good telescopic slides

When high quality telescopic slides are purchased, a series of advantages and benefits are obtained that result in higher performance and productivity at work.

Among these advantages it is worth mentioning :

Resistant materials: when a guide is manufactured with cold drawn, galvanized and tempered steel, we are talking about a material resistant to shocks and vibrations, with high rigidity and limited bending. It is a high quality product, designed to withstand daily use.

Longer service life: by acquiring a good quality product, not only a good performance of the guide is guaranteed, but also its service life to continue working for a long time. This is an extraordinary advantage, which in the end turns into significant savings, since you do not have to constantly change equipment.

High load capacity: good quality slides perfectly withstand the loads for which they were designed, thanks to perfectly installed systems made of highly resistant materials.

All these advantages help to optimize the work and make the company grow every day. These are the advantages of applying technology to the development of a company in its different functions.

This support is essential to improve many of the tasks that any industry or company develops, that is why when a system for moving objects or products is required, telescopic slides are an excellent option.

Knowing how they work, how advantageous they are and their multiple applications, if you have a company or business where you need to install a telescopic guide, you already know what to do and where to look for them.