A Comprehensive Guide On How To Use A CNC Machine

Continuing with the CNC machines, the rapid increase in use has led to low costs with increased production rates. The market’s fast growth also led to a rise in demand for different types, applications, and regions. It is due to the ease at which CNC machines can produce complex parts.

Overall, CNC machines are very popular. They allow for high-quality products at a low cost, thus removing many problems associated with traditional methods. Visit this link to visit an amazing library of CNC designs in DXF file format.

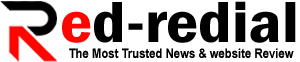

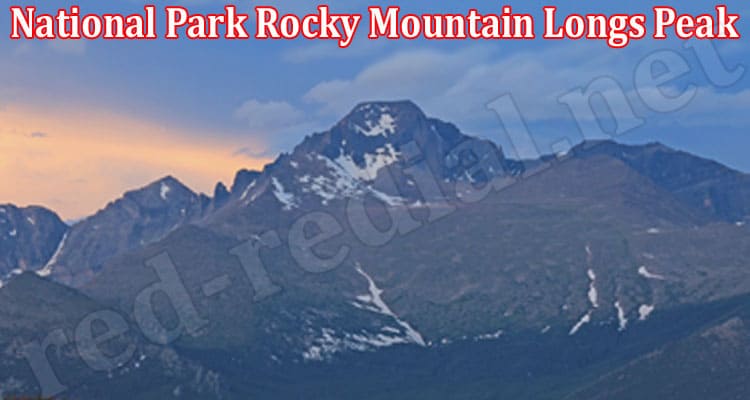

What Exactly is a CNC Machine?

CNC machines, in the simplest of terms, perform operations such as cutting and drilling. They make an object from a computer-designed drawing (DXF File). CNC machines are helpful in many different industries, such as the automotive and aerospace industry.

Understanding how these machines work can be broken down into two parts: the controller and the machining center.

The controller of a CNC machine is the piece of equipment that collects input from its rotating input sensors and feeds it into the machine’s computer. The software determines how to complete each movement, which changes the machining center’s movements along with it.

The controller uses servo motors to move its various custom tools around to complete the job.

Different Operations Performed On A CNC Machine

Turning

Turning is a process that involves using a rotating tool to shape the piece of material on the end of a spindle. The tool and the material move in a circular motion at a constant rate and angle. It leaves behind what we know as the concentric circular grooves on the piece of material. These grooves are just one of many ways that turning can be carried out.

Drilling

Drilling on CNC machines differs from drilling done on manual machines because CNC machines do not need an operator to hold onto it. Instead, computer commands control the whole operation. These commands then go to the machining center, which then directs the drilling tool’s movements.

Milling

The milling process is cutting many small pieces and mantle them together again. The difference between this and drilling is that instead of drilling, the CNC machine uses a feed-and-drag device to control the overall movement of its tool.

Grinding/Filing

Another different task that can be carried out on a CNC machine is grinding and filing. These processes smoothen the surface of an object, make it precise, and create entirely new smooth surfaces. Grinding and filing use an abrasive wheel and rotary tool to make minor cuts for this purpose.

Solid Sink EDM

A solid sink EDM can cut or drill a solid material with a rotating tool. The entire operation of the machine is the same as a standard CNC machine. The difference between a traditional CNC machine and a solid sink EDM comes down to cutting the material. A classic CNC machine will have one or more rotary tools that move around in relation to one another. On the other hand, a solid sink EDM has just one tool that only moves up and down on its axis without any rotation from another tool.

CNC Machine Basics

Some Fundamental CNC Processes:

Designing The DXF File

The design of a component is one of the most critical components of planning a studio’s CNC machine needs. It involves determining and programming the various details and handling the DXF file. The design process in CNC manufacturing is very similar to that of manual manufacturing processes.

Programming The System According To The DXF Files

The programming part is just as crucial as a DXF file because it involves determining each movement and how they will fit together to create a final product. It often requires trial and error with many different prototypes to get the right amount of movement while also being efficient enough for larger-scale projects that need to be completed within a certain period.

Running The Machine

Once the program with the DXF file is ready on the CNC machine, it’s finally time to run the machine. It involves putting the material on the spindle and cutting or drilling through it quickly and efficiently with no material loss. These machines are incredibly accurate, so a little experience on the machine would be best to get their full use out of them.

Cutting The Part

It is the phase where the precise movements of the CNC machine are carried out on the material for it to be cut with precision. It involves using various tools with different functions, which are coded in with the software. These movements are done at precise locations, leaving behind perfectly flat surfaces on all sides of the part.

Inspecting The Part

An internal inspection is performed after each cut or drill is complete. It allows for parts that are not being cut or taken off of the spindle either by manual or auto processes.

Conclusion

When looking at the entire process of using a CNC machine, it’s evident that it requires less human involvement, which is always better for any production environment. It can drastically reduce quality problems with machines not performing correctly or making mistakes during the final product.